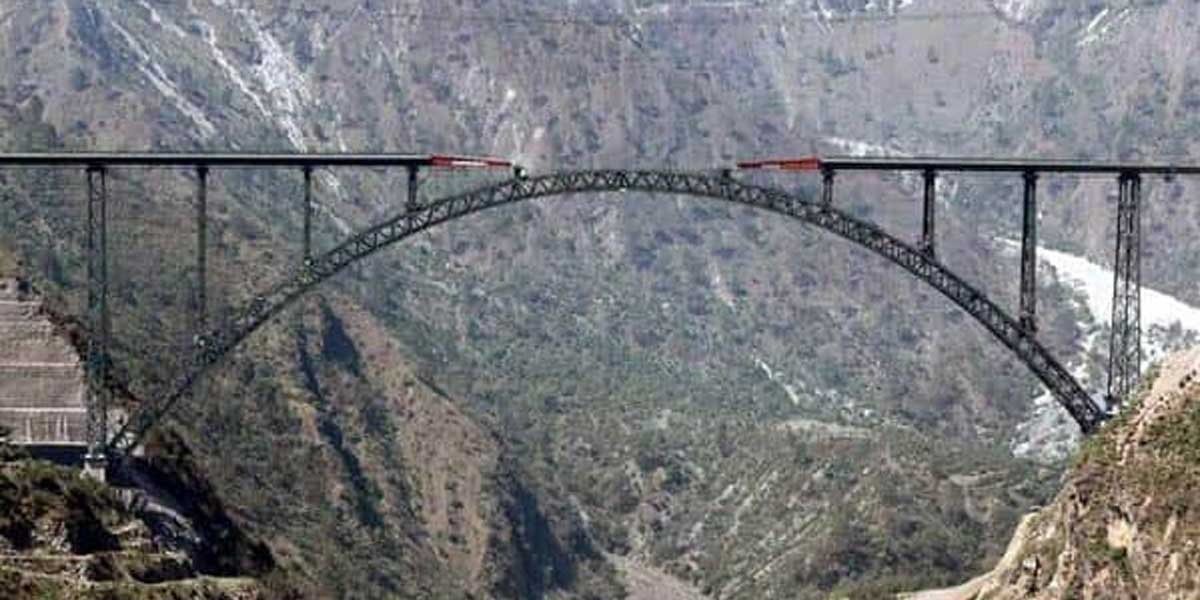

India will soon witness another milestone at the world’s

highest railway bridge, in Jammu and Kashmir, when the overarch deck launching of the Chenab Railway Bridge gets completed with a golden joint this month.

In the Chenab Bridge, 93 deck segments, each weighing about 85T, have been simultaneously launched from both ends of the valley over the mighty steel arch and five are in progress. Both ends will finally meet to complete the bridge overarch deck and the segments will be joined with the help of High Strength Friction Grip (HSFG) bolts to mark the golden joint. This will complete the bridge over the Chenab river valley and herald a new chapter in the history of Jammu and Kashmir.

“The overarch deck completion, 359m above the Chenab riverbed, will be an extraordinary achievement. I have my highest respects for every engineer and worker who have contributed in this engineering achievement. This golden joint will usher in a golden moment in the history of Indian Railways and will become a golden chapter in the history of Jammu and Kashmir. Construction engineering was completely done by Indian engineers which makes the Chenab Railway Bridge a symbol of Atmanirbhar Bharat,” said Giridhar Rajagopalan, Deputy Managing Director of Afcons.

Around 30,350 MT of steel has been used in the 1315m long Chenab Railway Bridge construction. 10,620 MT of steel has been consumed in the construction of the gigantic arch, and 14,504 MT of steel has gone into the construction of the bridge deck. The bridge, on the upstream of Salal Dam, is situated near Kauri village in the Reasi district of Jammu and Kashmir. The bridge is being constructed by Mumbai-based infrastructure major Afcons, keeping safety, quality and productivity as their main driving parameters.

“For the first time in Indian Railways, incremental launching was done on transition curve and a longitudinal gradient, both occurring at same location, for the deck launching of the viaduct portion of the Chenab Bridge. Typically, bridges have been constructed incrementally on a straight or a curved platform with a uniform radius. Executing launching activities in inclement weather & stormy wind conditions was extremely challenging,” Giridhar said.

Both Northern Railways (NR) and Konkan Railway Corporation (KRCL) had played a huge role in finalising the design of the iconic Chenab Bridge. Reflecting on their involvement at crucial stages of the bridge construction, Giridhar said, “We received tremendous support for any technical issue, approval for drawings, method statements, and most importantly, both NR and KRCL played an important role in generating local employment. KRCL constructed all the access roads to project site. These roads have provided connectivity to far-flung villages in the region.”

“The Northern Railways allowed us to use the Phased Array Ultrasonic Testing Machine for inspection of welds. This was done for the first time in India,” he added.

The fabrication was carried out in sophisticated workshops set up at both ends of the bridge. The heavy and bulky segments were transported to the launching pad with the help of SPMT, specialised modular trailer. “Considering the treacherous hilly terrain, temporary launching platform with segment lifting capacity of 120 MT and for a height of about 39m was designed. We developed and implemented a number of innovative methods to overcome the challenges of the hilly terrain for successfully executing our launching activities,”Giridhar said.

For the first time in India a fully equipped NABL laboratory was set up to ensure that quality was being monitored at every stage of the project. “The Northern Railways supported us in setting up the NABL lab at site for conducting weld sample tests. This saved a lot of time,” he added.

With KRCL’s support Afcons could carry out mock-up of all main bridge components before executing the original work which gave confidence to the engineers. This was super critical in ensuring quality and safety of staff and workers.

Once completed, the Chenab Railway Bridge will be 35m higher than the Eiffel Tower.

Besides completing the world’s highest single-arch railway bridge in Jammu and Kashmir, Afcons also holds the distinction of refurbishing Bihar’s iconic Mahatma Gandhi Setu and converting it into India’s longest steel bridge.

Also read:

Maldives inks pact with AFCONS for Greater Male Connectivity Project