Ammann Group to utilise 60% recyclable raw materials in building projects

Redefine the future of urban mobility! Join us at the Metro Rail Conference 2025 to explore groundbreaking ideas and insights. 👉 Register today!

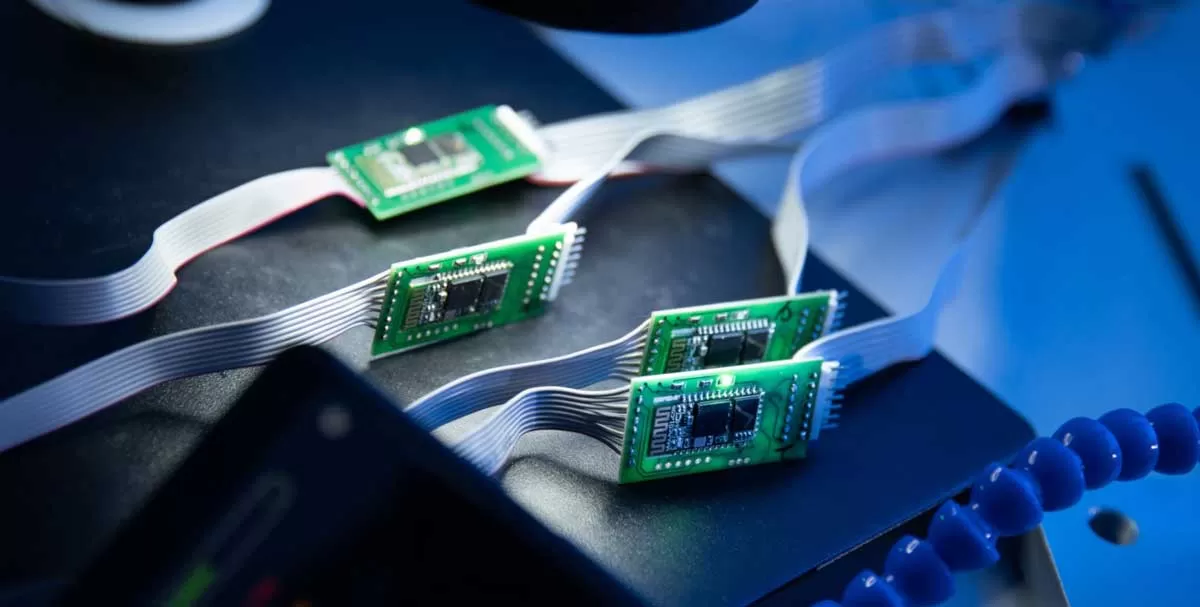

Maharashtra Builders Must Add Waterproof Telecom Centres In Buildings

The Maharashtra Urban Development Department (UDD) has issued a notice (dated 30 September 2024) inviting suggestions and objections regarding a proposed addendum to the Model Building Bye-Laws 2016, issued by the Ministry of Housing and Urban Affairs (MoHUA). The addendum is set to be incorporated into the Development Control and Promotion Regulations – 2034 for Greater Mumbai. Aimed at enhancing digital connectivity infrastructure in Mumbai and its suburbs, the notice calls on architects, developers, and town planners to provide input on the inclusion of Common Telecommunication Infrastru..

Year-End Review 2024: MeitY’s Digital Leap

In 2024, the Ministry of Electronics and Information Technology (MeitY) spearheaded significant initiatives to advance India's digital growth, with a focus on artificial intelligence (AI), cybersecurity, and skill development. These efforts aimed to democratise technology, foster innovation, and cement India's position as a global technology leader. Semiconductor Manufacturing under the Semicon India Programme Several major projects received approval under the Semicon India Programme, marking a pivotal year for semiconductor manufacturing in India: 1. Tata Electronics Private Limited (TEPL)..

Indian Railways to Roll Out Kavach 4.0 For Safer Rail Operations

Indian Railways is advancing efforts to boost safety and operational efficiency by deploying the state-of-the-art Kavach 4.0 automatic train protection system across key routes. The enhanced system, developed in-house, aims to prevent accidents, minimise human error, and ensure seamless train operations. According to officials, all locomotives equipped with earlier versions of Kavach will be upgraded to Kavach 4.0. The North-East Frontier Railway has identified approximately 1,966 route kilometres, stretching from Malda Town to Dibrugarh, for implementation. This initiative is part of a br..