UK engineering firm Taziker has developed a unique methodology for replacing worn track on The Big One roller-coaster in Blackpool. Point-cloud data and BIM technology combine to ensure the roller-coaster opens on time each year with a smooth ride for visitors.

Roller-coaster tracks take a beating during the amusement-park season.

The trains are heavy when packed with people, bringing multiple tons of force to bear down on the track. This force is greatest at points where the track dips and turns. Here the steel is constantly tensing and flexing, over time leading to small surface cracks that can cause a bumpier ride.

This is why Blackpool Pleasure Beach, one of the UK’s leading amusement parks, annually refurbishes sections of the track on one of its main attractions: The Big One. When it opened in 1994, The Big One was the world’s tallest and steepest roller-coaster. Its highest point is 65 meters, with a drop angle of 65 degrees. More than 10 million runs have taken place on The Big One, which is still the tallest rollercoaster in the UK.

Since 2019, engineering firm Taziker has been responsible for replacing any worn track with newly manufactured sections. Taziker has developed a unique method for doing this, as Managing Director and The Big One project manager Jarrod Hulme explains, “We came up with a completely new way of addressing this by capturing a 3D point cloud of the track that needs to be replaced. “We started off using the Trimble SX10 and now we’re using the Trimble X7, capturing millions of location points that we then use to model the steelwork. These Trimble products are nicely integrated with Tekla software.”

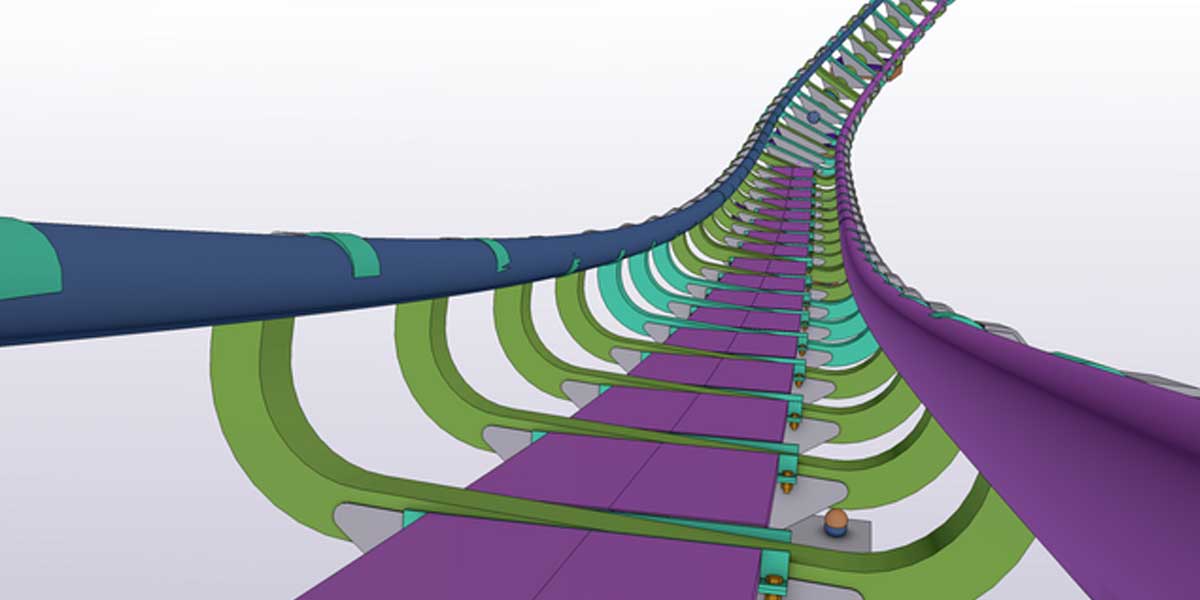

“In Tekla Structures we place the point-cloud analysis on top of the existing model. By mirroring the ride in this way we can detect any bumps or kinks in the old structure, and then produce new track that perfectly matches the original geometry,” says Hulme.

More data, fewer errors, smoother rides

The Taziker methodology is a radical departure from how the track replacement work was done in the past. Previous vendors would take the old track out, measure it by hand, and then fabricate new track. Even small measurement errors could make a big difference, resulting in track that would not fit when it came time for installation.

In the latest replacement round, the rollercoaster needed nine new pieces of track at a total length of 75 m. Taziker also increased the thickness of the running rails by 50 per cent and added 50 per cent more ties. These changes make the track a lot stronger and reduce the amount of fatigue it’s subject to over the years.

“While the curves on a roller-coaster look round, they’re actually made up of lots of individual straight pieces called facets,” says Hulme. “The idea is to make the transitions between these facets as smooth as possible, so the rider has a feeling of floating on air.”

Taziker does its point-cloud work when Blackpool Pleasure Beach is closed for the winter. The new track is then manufactured through the summer while the park is open. When it closes again, the old track is removed and the new track is delivered and installed. This schedule means the theme-park owner does not lose any revenue by having a ride that’s closed during peak months.

“We’ve tapped into a very niche market here. I don't believe there's anybody else on the planet using 3D point clouds to get information from existing roller-coasters, transferring the data into 3D models, and then using it to produce new pieces,” says Hulme.

Automation from start to finish

The Taziker engineering team has heavily automated both the model creation process and the fabrication work. Parts created in Grasshopper are easily replicated in Tekla Structures. The data is then exported to a Total Station on the shop floor where the geometry is confirmed with laser technology.

“The integration between Tekla and Grasshopper is excellent, and we’ve used it to create code that automates our model creation. This reduces our modeling time by at least 50% compared to when we started doing this track renovation work some five years ago,” says Hulme.

“Each year we’re finding even better ways to get the software from the cloud into Tekla, and then on to the shop floor for fabrication,” he says. “All Taziker’s fabrication is done digitally using lasers for precision measurements, based on the data provided by Tekla Structures. We work to a tolerance of plus or minus two millimeters.”

“While structural steel fabricators mainly use Tekla Structures to create models and drawings, we use it to pretty run our whole business. Tekla Structures does so much more than only modeling,” says Hulme.