The unique Upflow Anaerobic Sludge Blanket technology treats organic wastewater.

The cliché, ‘Water, water, everywhere, not a drop to drink’, is more often than not true in today’s world. The silver lining, though, is that water, once treated, can be reused for industrial and domestic purposes. The Upflow Anaerobic Sludge Blanket (UASB) is one technology that helps make this possible.

AHLAM RAIS explores the benefits of this purely biological wastewater technique in conversation with

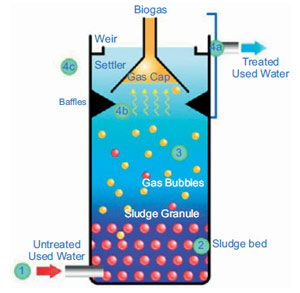

K Karthikeyan, JCEE, Tamil Nadu Central Pollution Control Board.Explaining the process: Under anaerobic conditions, organic pollutants in wastewater are degraded by microbes producing methane and carbon dioxide. The degradation process is effective compared to the more conventional aerobic processes and produces only 5-10 per cent of sludge. Among anaerobic technologies, the most popular is UASB technology. In this technology, the waste to be treated is introduced in the bottom of a reactor. The wastewater flows upwards through a sludge blanket composed of biologically formed granules or particles. The treatment occurs as the waste comes in contact with the granules. The gas produced under anaerobic conditions causes internal circulation that helps in the formation and maintenance of the biological granules. Some of the gas produced within the sludge blanket becomes attached to the biological granules. The free gas and the particles (with the attached gas) rise to the top of the reactor. The particles that rise to the surface strike the bottom of the degassing baffles that release attached gas bubbles. The degassed granules drop back to the surface of the sludge blanket. The gases released from the granules are captured in the gas collection domes located at the top of the reactor.

Basic requirements: The basic requirement of this technology is that the water that has to be treated should have organic content. Parameters such as voluntary fatty acids, total alkalinity, etc need to be monitored and controlled for effective treatment. Apart from this, the stability of the reactor should also be tested. For this, an enclosed treatment system along with three compartmental systems is required. All these are important parameters that have to be looked into. In this process, first the wastewater is pre-treated by removing suspended solids and then emptied into another big digestor (rector). The wastewater is treated to reduce the biological oxygen demand (BOD) at the rate of 25 kg per metre of the reactor per day. The reactor should be configured in such a way that the total height does not exceed 6 m or above. Additionally, a distributer is positioned at the bottom of the reactor. The treatment efficiency of this technology depends on the volume of the reactor. Per cu m of the reactor can accommodate 25 kg of BOD, this is a limitation. Depending on the flow rate and the retention time which can be kept at four hours, the volume of the reactor could be arrived at. It can range from 1,000 -2,000 cu m.

Applications: UASB technology is adopted for treating the wastewater of sewage boards under the guidance of the government. It is also used in industries and factories for treating water and reusing it for industrial purposes. Apart from this, it is used in the dairy, beverage, sugar and chocolate industries.

Green features: Biogas is a by-product of this technology and is generated from the organic carbon available in the wastewater. Every kilogram of BOD generates .35 cu m of biogas with the assistance of this technology. Depending on the total quantity of water and volume of the reactor, one can judge the total kg of biogas that will be generated. In this process, there are three bacteria involved: acidogenic, acetogenic and methanogenic bacteria. All three together undergo a hydrolytic process where all the organic compounds are disintegrated into smaller particles and then converted into acidic elements. They are then converted into biogas (methane and hydrogen) along with carbon dioxide.

Bonus points:The Ministry of Urban Development has recommended this technology as one of the options for sewage treatment plants. Apart from this, the biogas produced through this technology proves beneficial to generate electricity; it can also be used for cooking purposes, thus replacing the use of fossil fuels. USAB technology also helps reduce hazardous emissions such as sulphur dioxide, nitrogen oxide, etc. This technology also has the least impact on the environment. It is energy-oriented and cost-effective, and the treatment cost is also less.

Cost: This technology is highly cost effective as compared to conventional technologies. Where conventional technologies cost Rs 25,000-35,000 for treating per cu m of wastewater, this technology requires Rs 18,000-20,000. UASB technology requires an area within 2,500 sq ft. The cost of this technology will vary depending on the quantity of water treated. The price of running this technology is also cheap.

Challenges: Most Indian states cannot accommodate land for this technology. The level of awareness about this technology is less and, hence, it should be promoted. Effective monitoring and knowledge along with basic training have to be given to people to optimise the use of this technology.

To share your technology with us, write in at

feedback@ASAPPmedia.com