Shifting preferences for tippers and dump trucks

Signature Global Prime Earns IGBC Platinum Certification for Sustainability

Signature Global (India) has achieved IGBC Platinum certification for its affordable housing project, Signature Global Prime, in Sector 63A, Gurugram. This milestone makes it one of the few affordable housing projects in India to earn the prestigious recognition.Spread over 5.7 acre, Signature Global Prime consists of 817 residential and 118 high-street retail units. The project advanced from Gold to Platinum certification by excelling in energy efficiency, water conservation, eco-friendly materials, and sustainable design.Lalit Aggarwal, Co-founder & Vice Chairman, stated, ""This achievem..

Merino’s Special Laminates: Redefining Modern Interiors

Merino’s Special Laminates offer a perfect blend of aesthetics, durability, and functionality, making them a preferred choice for architects and designers. With diverse textures, patterns, and finishes, these laminates cater to varied design preferences—from minimalistic to bold interiors.Diverse Product RangeMerino’s collection includes:Sampada: Traditional Indian-inspired patterns.Luvih: Satin-smooth, fingerprint-resistant matte laminates.Infusio: High-definition, vibrant surface designs.Laminature: Realistic natural textures.Metalam: Sleek metallic finishes.Tuff Gloss MR+: High-gloss,..

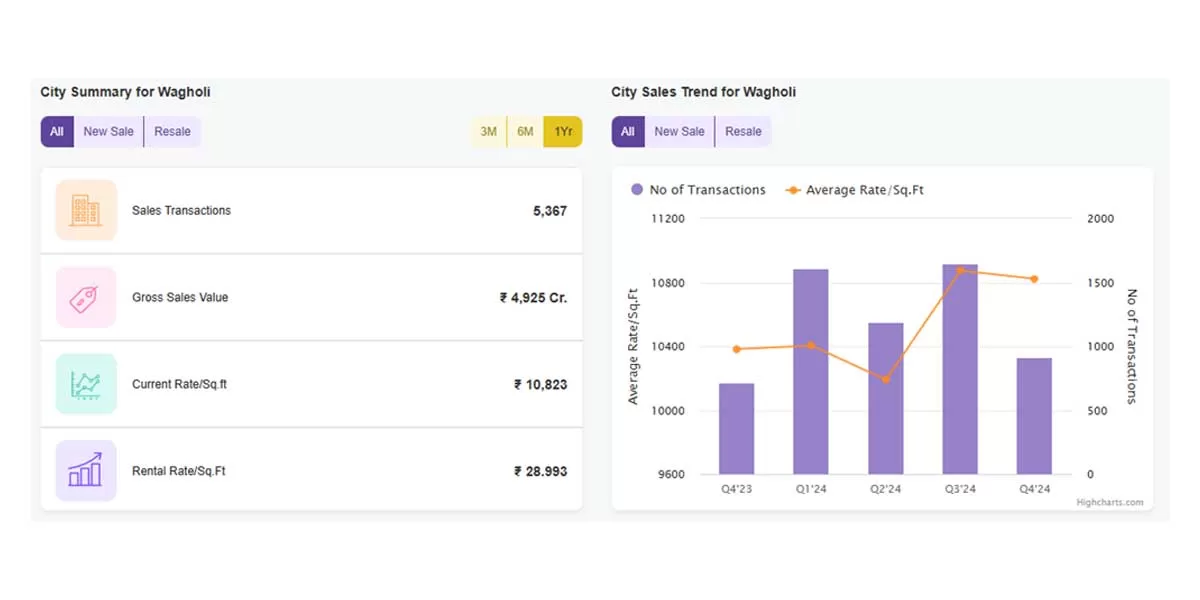

Casagrand Millenia Acquires Wagholi Land for Rs 1.26 billion

Casagrand Millenia has acquired a 1.18-ha land parcel in Wagholi, Pune, for Rs 1.26 billion (bn), as per property registration records. The transaction, involving a stamp duty of Rs 88.2 million and a registration fee of Rs 30,000, was finalised in January 2025.Anand Moorthy, Co-founder and CBO, Capital Market & Services, Square Yards, said, “Pune’s eastern micromarket is emerging as the most dynamic commercial hubs, witnessing the highest office offtake in the city. This surge coupled with well-developed physical and social infrastructure, seamless connectivity via the Pune-Ahilya..