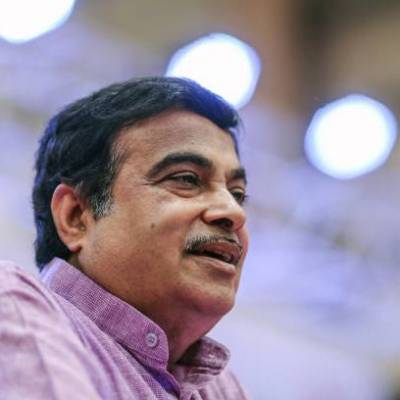

Minister of Road Transport and Highways, Nitin Gadkari, inaugurated a unique first-of-its-kind mobile cold mixer cum paver and patch-fill machine, which has been developed indigenously by Central Road Research Institute (CRRI) to repair potholes.

According to the officials, the machine can repair 12-15 medium-sized potholes within one hour and is the best solution for roads and highway maintenance. Gadkari stressed the need for developing cost-effective technologies for road construction by using locally available materials to reduce dependence on cement and steel. Gadkari asked the road research institute to focus on long-span bridges and find ways to resolve the problems faced by bridge expansion joints. He added that the research and development should not only end at filing patents but should also be commercialised to be available in markets, and more agencies use it for the construction of roads and repairing potholes. The machine is a part of the Make in India initiative at Rs 30 lakh per unit, with a material cost of Rs 600 per tonne, compared to imported machines that cost Rs 2 crore with Rs 1,000 per tonne material cost. CRRI officials said that the road construction agencies in India use the traditional method for repairing potholes by employing manual labour. The compact and low-cost pothole repair machine uses bitumen emulsion-based cold mix technology, which is self-propelled and self-contained. Officials said that the machine would help in constructing roads in high-altitude regions where the design and construction of roads are challenging compared to plain terrain due to the non-availability of skilled labour and lack of space. It will also help in reducing carbon emissions and curb air pollution. Image Source