CCI Clears Ambuja Cements' Plan to Acquire 72.8% Stake in Orient Cement

The Competition Commission of India has approved Ambuja Cements's proposed acquisition of up to 72.8 per cent shareholding in Orient Cement. Ambuja Cements, a leading manufacturer of grey cement, produces Ordinary Portland Cement (OPC), Pozzolona Portland Cement (PPC), and Pozzolona Composite Cement (PCC). The company, along with its subsidiaries, operates 22 integrated cement plants, 10 bulk cement terminals, and 21 grinding units across India. Orient Cement specializes in the production of grey cement, including PPC and OPC. The company operates three manufacturing facilities in Devapur ..

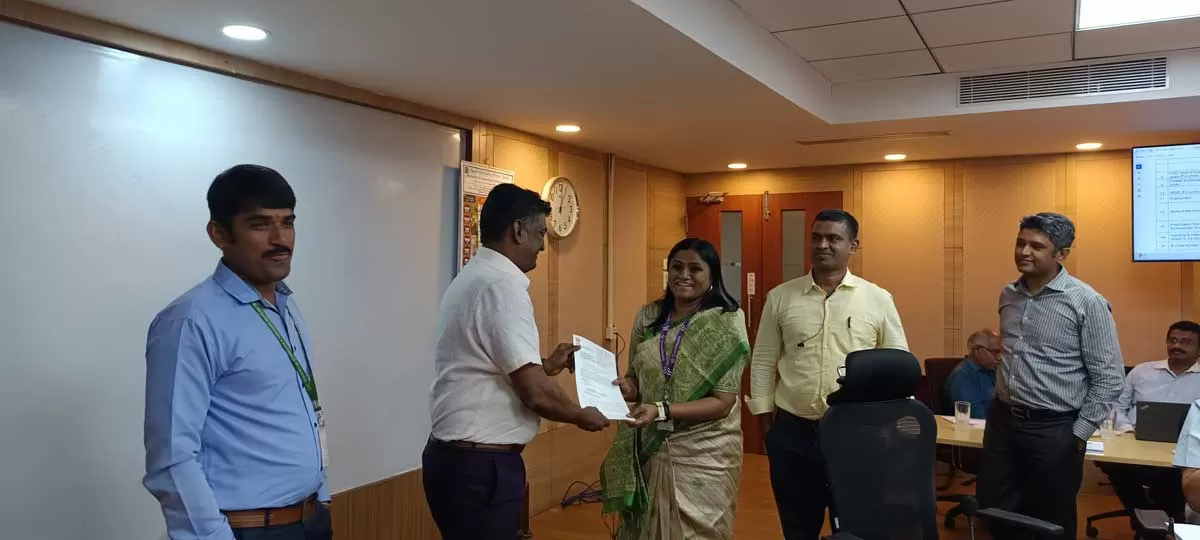

MEPZ Approves Rs 21 Crore New investments

At its latest Unit Approval Committee (UAC) meeting held on 3rd March’25, MEPZ SEZ reaffirmed its vision for inclusive industrial progress, approving Rs 21 crore in new investments and opening up 642 jobs in Tamil Nadu. But this meeting was about more than just business. With the approval of jobs for 10 transgender individuals, MEPZ SEZ continues to build momentum in fostering a truly inclusive workforce. This step strengthens the ongoing efforts to ensure equitable opportunities for all.""Inclusion isn’t just the right thing to do—it’s the future of industry,"" said Thiru. Alex ..

Cabinet Approves Ropeway Project from Sonprayag to Kedarnath

The Cabinet Committee on Economic Affairs (CCEA), chaired by the Prime Minister Shri Narendra Modi, has approved the construction of 12.9 km ropeway project from Sonprayag to Kedarnath (12.9 km) in Uttarakhand. The project will be developed on Design, Build, Finance, Operate and Transfer (DBFOT) mode at a total capital cost of Rs. 4,081.28 crore. The ropeway is planned to be developed in public-private partnership and will be based on the most advanced Tri-cable Detachable Gondola (3S) technology with a design capacity of 1,800 passengers per hour per direction (PPHPD) carrying 18,000 passenge..