- Home

- Infrastructure Transport

- ROADS & HIGHWAYS

- What keeps mega projects on track!: Detailed report

What keeps mega projects on track!: Detailed report

Photo courtesy: L&TThe year 2019 saw several mega projects cross the finish line. These include Bogibeel Bridge (completed December 2018), the Lucknow Metro (launched March 2019), the Hyderabad Metro (~25 km of 72 km completed in 2019) and, most recently, the Motera (Sardar Patel) Stadium (inaugurated February 2020), to name a handful.Some of these projects stand out for their size. Bogibeel is Asia’s second-longest road and rail bridge. Motera is the world’s largest cricket stadium seating 110,000. And so on.These were a handful of the predominantly road, bridge, power, urban, digital infrastructure and railway projects that saw the Indian Government spend Rs 80 lakh crore on infrastructure between FY08 and FY19.In particular, what helped these projects get done in time, more or less?“Appropriate project planning, technology and a clear execution methodology, including government initiatives like timely land clearance and incentives for on-time completion, helped these projects get done fast,” responds Vinay HP, Senior Consultant, Industrial Practice, Frost & Sullivan. “The Lucknow Metro covering 22.87 km across 22 stations is the fastest built metro rail system in the country.”Let’s consider each of these major factors.Availability of landLand is a sellers’ market. When Hero Future Energies set out to acquire land for a 78.8 mw wind solar hybrid system in Raichur, Karnataka—successfully commissioned in 2018—the company had to contend with fairly aggressive landowners who knew land parcels adjacent to an existing 50 mw wind project would be needed to set up a 28.8 mw solar plant.Several upcoming mega projects such as Mumbai’s Trans-Harbour Link and Coastal Road, some phases of Bharatmala and Sagarmala, the Diamond Quadrilateral, the bullet train and the Delhi-Mumbai Industrial Corridor are facing land acquisition issues. “It takes a lot of time just to create work fronts, which leads to high cost implications,” observes Vipul Gakkhar, Infrastructure Consultant. He cites the Kishanganga hydropower project and a few phases of Bharatmala as mega projects that saw minimal delays because they faced minimal land acquisition and external approval issues. Phases of Bharatmala that were successful in his view, like the Rewa-Katni-Jabalpur-Lakhnadon Road, were road extension projects involving minimal land acquisition. The Kishanganga hydropower project is remotely situated in an area that was already under government control, so no extra approvals were required. In the roads sector at least, the newer hybrid-annuity mode (HAM) of executing projects has significantly helped ease land acquisition by stipulating that the appointed date will be announced only after the Government has acquired at least 80 per cent of the right of way, observes Rajeshwar Burla, Vice-President, ICRA.Burla cites some examples of projects that have benefited from this policy amendment: the four-laning of the Lucknow-Sultanpur section of NH-56 (127.4 km) completed in April 2019; the four/six-laning of the Kharar-Ludhiana section of NH-95 (76.01 km) completed in July 2019; the four-laning of the Yavatmal-Wardha section (64.93 km) completed in August 2019; and Package 3 of the Delhi-Meerut Expressway completed in September 2019.“HAM marks a significant departure from the earlier BOT or annuity models, wherein contractors would typically start working even prior to the major acquisition of land, only to face stalls when contiguous land parcels were unavailable,” continues Burla. “Idling causes cost overruns, reduces profitability and extends project timelines.”“The newer HAM also stipulates that if the NHAI is unable to acquire the remaining 20 per cent or so land parcels within 180 days of the appointed date, that part of the project can be descoped,” he adds. “While this is pro-project completion, it would inconvenience users and increase the completion cost to the NHAI, thus creating challenges in implementing de-scoping.”Burla also cites the Right to Fair Compensation and Transparency in Land Acquisition, Rehabilitation and Resettlement Act 2013 as a policy favouring landowners but hampering the completion of projects by increasing the cost of land acquisition more than four times and delaying the process when those compensated earlier at a lower rate demand higher pay-outs in lieu of leaving their land.Government supportProactive support from both the power and renewable energy ministries and strong support from state governments for land acquisition and to create power evacuating infrastructure are the key reasons for the timely completion of mega solar plants and parks in Rewa, Charanka, Pavagada, and Bhadla, observes Balawant Joshi, Managing Director, Idam Infrastructure Advisory.Government involvement can even push slow or stuck projects towards completion. As an example, Vinay cites Mission Bhagiratha (launched August 2016 and completed end 2019), a project that aims to provide safe drinking water to every household in Telangana through the creation of an intricate network of canals, overhead tanks, water treatment plants, and a pipeline grid running thousands of kilometres across the state. This Rs 45,000 crore project was initially delayed. But a push from the chief minister’s office set things rolling. It went on to set a record for producing more than 1.5 lakh cu m of concrete in a day and saw multiple large contractors such as L&T, Afcons, etc. work in tandem with each other. Access to reasonably priced financeInformation put out by construction companies suggests that, in 2019, liquidity issues reduced the overall project execution rate of most NHAI projects and other mega projects by 20-25 per cent vis-à-vis 2017 and 2018, shares Vinay. “January 2020 slowly showed some signs of improvement when the Central Government released contractor payments.”For projects to be completed on time, Gakkhar sees the need for a mechanism to track funds made available to contractors, to ensure that funds are used as earmarked and not for other projects, as tends to happen.Joshi expects two outcomes of the ongoing Covid-19 outbreak—labour scarcity and a paucity of finance—to create challenges in the execution of upcoming renewable power projects worth Rs 35,000-40,000 crore. The Government must address both of these issues.Subterranean uncertaintyAnother spoilsport factor is uncertainty surrounding subterranean conditions. “All mega infra projects necessitate deep digging for piling, and, in that, uncertainty rules. Unprecedented factors cause cost overruns,” observes Gakkhar. Essentially, every infrastructure project is unique as there are so many project-specific challenges. Those implementing such projects don’t really have a learning curve to climb as those implementing real estate do, making infra very difficult to execute. Hero Future Energies encountered hard strata during construction on acquired land for a solar power project, which made it very challenging to excavate trenches needed to run cables and water pipelines for the cleaning system.Subterranean uncertainty may be surmounted by analysing the situation and opting for the quickest, most cost-effective and sure solution.While constructing Medigadda Barrage—the largest barrage of the Kaleshwaram Lift Irrigation Project, a mega initiative to tap the flood waters of the Godavari river for drinking water and agricultural purposes, to serve more than two-thirds of the state of Telangana—L&T found that the construction of the raft foundation required ground improvement. “The geotechnical investigation revealed certain weak areas in the ground strata that required strengthening,” explains SV Desai, Senior Vice-President & Head – Heavy Civil Infrastructure IC, L&T Construction. “While methods like vibro compaction, dynamic compaction or rapid impact compaction were available, they are also time-consuming and costly. After a thorough analysis, we adopted the cement stabilisation dry-and-wet method.”Three barrages included in the project, the Medigadda, Annaram and Sundilla barrages, 19 reservoirs and 20 lifts have been executed within the estimated timelines and budget. However, by the time certain extra works are completely constructed, the total spend may exceed the original budgeted cost of Rs 80,499.71 crore by up to 30 per cent.Technological expertiseTechnology (apart from design methodology and approach) is a key criterion for the selection of contractors for mega projects. Interestingly, technology can influence the design methodology and approach.Indian contractors typically did not prioritise project planning, which is crucial for mega projects, and are highly price-conscious, hence only willing to consider upgrading technology if it lowers operational costs, observes Vinay. To some extent, the prequalification criteria established to assess the contractor’s potential performance compels them to adopt technology.Now, Vinay sees that contractors have begun integrating technologies and Internet of Things (IoT) into a detailed project plan and adopted digitalisation during the planning stage. Some technology advancements the industry is looking forward to, according to him: green construction technologies; wider specification of the use of modular and prefabricated construction techniques; autonomous construction, integration of drones, virtual reality, and wearables; 3D printing; and building information modelling (BIM) for better interpretation, coordination and planning.Leaders are already making use of these technologies. A major factor in the timely construction of the Motera stadium by L&T was the effective use of precast engineering. Subrata Datta, Project Director, Motera Stadium, L&T, elaborates: “What’s unique about this stadium are the huge HY (36 m high, 15 m wide and 1 m deep) and GY columns that form the outer façade with as many as 178 structural connections weighing in excess of 285 tonne that were precast in steel moulds. Casting one such column in situ would have taken the project team at least two months; with 43 such columns to erect, that was not an option. With precast technology, the casting was reduced to just two days. The greater advantage was that the columns gained the required strength in only 10-12 days.”The columns enjoyed all the advantages of precast technology such as standardised delivery, enhanced quality, superior aesthetics, improved safety and operational efficiency, adds Dutta.Joshi sees growing scope for drone-based technology to monitor renewable energy projects in forest and hilly areas, and for greater automation in solar plants to counter labour shortages.Technologies that helped L&T complete Medigadda Barrage in a record 24 months include automation and optimised formwork that cut the cycle time for the construction of a single pier. All the sequential activities of cutting, bending, rolling, welding and painting to fabricate the HM radial gates involving 26,000 mt of structural steel were fully automated. Instead of a conventional 2.4 m formwork height, an optimised formwork height of 5 m was adopted to speed up execution. Later, the formwork height was raised to 7.5 m and further to 10 m to achieve a concrete pour of 4,045 cu m.Implementing new technologies will be tricky, cautions Vinay, because it will necessitate integration across the ecosystem, rationalisation, standardisation, building digital talent, securing digital adoption, and establishing the value and return on investment.Digital technologiesDigital technologies are a key enabling factor of every major L&T project, including the Medigadda Barrage. “Digital technologies have helped L&T improve the utilisation of machines by at least 10-15 per cent and additionally reduce costs, cut wastage, avoid rework and, most important, reduce execution time,” shares S Anantha Sayana, Chief Digital Officer, L&T. These digital technologies include IoT, artificial intelligence (AI), augmented and virtual reality, RFID (radio frequency identification), QR codes, geospatial technologies like LiDAR (light detection and ranging), photogrammetry, drones, etc. Technology helps track men, material and 11,000+ machines across project sites streaming real-time data that is fed into a data engine (aptly named Alchemy) and displayed on business intelligence-powered intuitive and user-friendly dashboards.“Our ultimate digital vision is to have a ‘connected workman’ who with his ‘wearables’ [sensors and beacons] can be tracked for location and health status, and hence play a vital role in ensuring his safety and productivity by preventing him from venturing into no-go zones, and deploying or resting him respectively,” he explains.Infra development after COVID-19COVID-19 has brought projects to a standstill. Equipment fleets are lying idle. Migrant workers have fled. At what pace will work resume? Will players engaged in mega projects that are underway see extensive time and cost overruns?Vinay emphasises the need to maintain dormant equipment through the lockdown to resume work speedily thereafter. Completing pending project documentation and upgrading the skill sets of employees would also help ensure faster execution when construction resumes. Here’s to getting back to work!Upcoming mega projectsRoads (19.64 per cent), urban and housing (16.29 per cent), railways (13.69 per cent), conventional power (11.76 per cent), renewable energy (9.30 per cent), and irrigation (7.73 per cent) are among the sectors allocated more than 5 per cent each of the total spend envisaged under the National Infrastructure Pipeline.Here’s a run-through of the proposed mega projects by sector:• Roads: Delhi-Mumbai Expressway, Chennai-Bengaluru Expressway• Power: Dibang Hydel Power Project, high voltage direct current (HVDC) bipole link project (transmission)• Petroleum and natural gas: Strategic petroleum reserve at Chandikhol, Jagdishpur, Haldia and Bokaro Dhamra Natural Gas Pipeline• Atomic energy: Four new reactors at the Kudankulam Nuclear Power Project• Railways: Dedicated freight corridors, high-speed rail• Ports: Vadhavan Port• Airports: Navi Mumbai, Jewar• Urban: Surat Metro, Kanpur Metro, affordable housing, Jal Jeevan Mission (urban)• Irrigation: Ken Betwa, Godavari Cauvery river linking, Clean Ganga, reservoir projects• Digital infrastructure: Bharat Net• Rural infrastructure: Jal Jeevan Abhiyan (rural), Pradhan Mantri Gram Sadak Yojana, Pradhan Mantri Awas Yojana - GraminTechnology: Gamechanger in renewable powerSo far plants are typically solar or wind-based. But generation from any such individual plant depends on the availability of natural resources. So there is a strong need to keep renewable power reliable for firm generation, explains Atul Raaizada, President, Project & OMS & New Technologies, Hero Future Energies. Thus, hybrid plants evolved where one can choose renewable sources that complement each other to fulfil the requirement of near firm power. And these would be more reliable as solar can generate energy only during the day while wind can generate energy round the clock.“In future, the key is to set up true hybrid plants where the same inverter of the wind plant becomes common with the solar plant with its BOP (balance of plant) system to service wind generation and solar generation with an efficient and proportionate ratio,” he adds. “This kind of system will remain more cost-effective with higher yield to cope up the floor prices equivalent to other electricity generation mechanism. In future, the increasing efficiency of batteries will add another dimension into such a hybrid system to make a more reliable tribrid system where energy storage facilities enable both plants to work simultaneously to generate energy—one plant to feed the grid and the other to feed storage. Thus, the intersystem curtailments will be controlled and support the grid network when demand peaks.”Raaizada foresees the emergence of virtual power plants, technology that aggregates scattered energy-generating units on one common computerised platform. He sees a role for microgrid solutions in hybrid plants and the evolution of a packetised system where the generation of energy is scheduled on the basis of predeclared, precalculated, atomised consumption patterns from different DISCOMs and captive sources. He also expects tariffs to be linked with energy management systems to decide how much energy should be generated from what source.“When India embarks on offshore wind plants, which is a matter of time, contractors seeking a slice of the pie will need to acquire the skills to construct floating rigs, underwater foundation construction technologies, and material handling technologies to lift the individual components of the wind turbines,” adds Balawant Joshi, Managing Director, Idam Infrastructure Advisory. “These skills will need to be imported/acquired from the UK and Nordic nations.”

Jyoti Structures Commissions Galvanisation at Second Nashik Unit

Jyoti Structures has commissioned galvanisation operations at its second tower manufacturing unit in Nashik, strengthening its in-house capabilities across critical stages of power transmission infrastructure production. The listed Engineering, Procurement and Construction (EPC) company operates globally and has delivered projects for customers across more than 50 countries.The second Nashik unit, with an annual manufacturing capacity of 36,000 metric tonnes, has become operational following the completion of installation, testing and readiness of the new galvanising facilities. With this deve..

Rosatom Connects First Kursk NPP-2 Unit to National Grid

Rosatom has launched the first power unit of the Kursk Nuclear Power Plant-2 (Kursk NPP-2) into Russia’s Unified Energy System, marking a key milestone in the country’s nuclear energy programme. The initial grid connection took place at the end of the year, bringing a new source of low-carbon electricity online for the Kursk region and the broader Central Energy System.The newly commissioned unit is the first implementation of the VVER-TOI reactor design, which incorporates advanced safety and performance features. With an installed capacity of 1,250 MW, it is the most powerful nuclear pow..

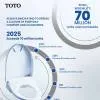

TOTO Crosses 70 Million WASHLET Sales as India Fuels Growth

TOTO has announced that global shipments of its WASHLET range have surpassed 70 million units, marking a major milestone in the brand’s more than four decades of innovation in bathroom hygiene and wellness. Headquartered in Japan, the company supplies WASHLET products across residential and public restroom applications in over 100 countries, with rising demand across the Americas, Europe and Asia.The milestone reflects a global shift toward higher standards of hygiene, comfort and wellness. While overall demand continues to grow worldwide, India has emerged as one of TOTO’s fastest-growing..

Latest Updates

Recommended for you

Advertisement

Subscribe to Our Newsletter

Get daily newsletters around different themes from Construction world.

Advertisement

subscribe to the newsletter

Don't miss out on valuable insights and opportunities

to connect with like minded professionals